Manufacturing Process

Powder Metallurgy

This process involves compaction and sintering as the primary steps, followed by machining and various heat treatment processes to produce high-quality parts.

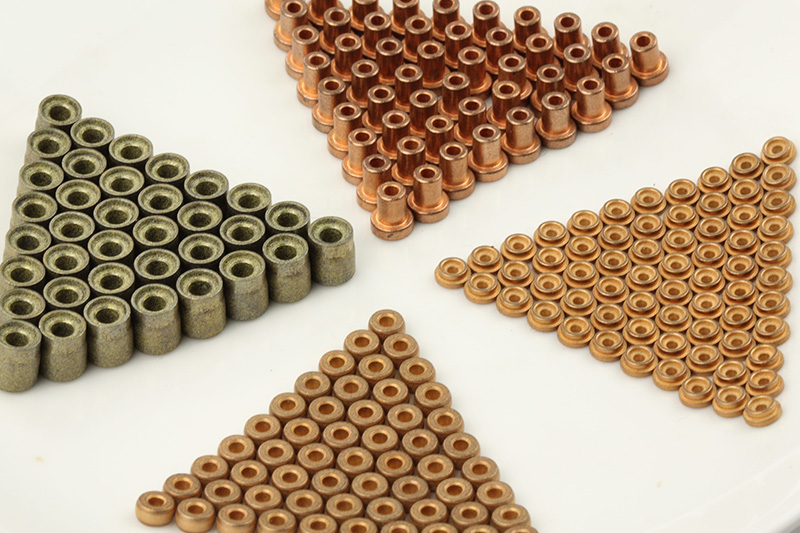

Manufacturing of Micro Bearings

Using small-tonnage compaction machines, the process involves sintering and machining to produce the final product. Subsequently, the bearings undergo oil impregnation or vacuum oil impregnation to ensure that the pores are fully saturated with oil. This step is crucial for providing lubrication during operation.

Metal Injection Molding (MIM)

Using self-mixed raw materials, the material is injected into molds through injection machines and then undergoes de-waxing and sintering to produce finished products.

Process for Fuel Cell Interconnect Plates

Specialized in producing metal interconnect plates for fuel cells, this process uses the largest 1600-ton compaction machine in Taiwan's industry.

Metal 3D Printing

Porite Taiwan provides comprehensive gearbox assembly services for major power tool manufacturers and motor clients using specialized assembly equipment and a professional team.

Metal Foam

Also known as porous materials, metal foam has a wide range of applications and represent Porite Taiwan's latest development process.

High Density & High Performance Powder Metallurgy

Using special raw materials in traditional powder metallurgy manufacturing, this process produces parts with density and strength far exceeding those of general powder metallurgy processes. Precision can reach the highest JIS4 standard, making it ideal for producing high-precision small gears.

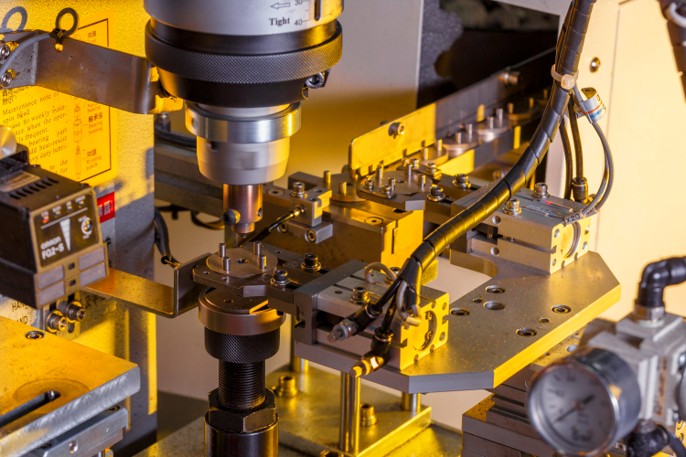

Gearbox Assembly

Using special raw materials in traditional powder metallurgy manufacturing, this process produces parts with density and strength far exceeding those of general powder metallurgy processes. The precision can reach the highest JIS4 standard, making it ideal for producing high-precision small gears.