HPM, which stands for High Density and High-Performance Powder Metallurgy, is a cutting-edge process that can produce parts with densities comparable to those made by metal injection molding, using traditional powder metallurgy techniques. The precision and strength of these parts far exceed those of conventional powder metallurgy components, making HPM particularly suitable for manufacturing parts that require high strength and high precision.

Complementarity with Existing Processes:

Advantages Comparison:

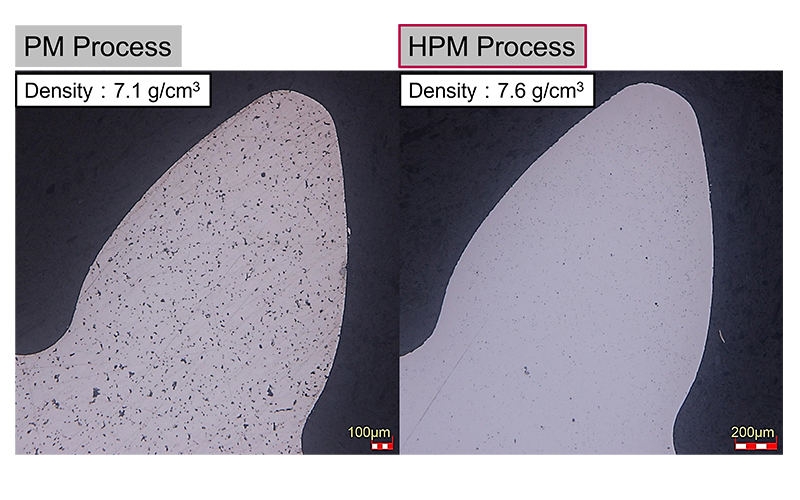

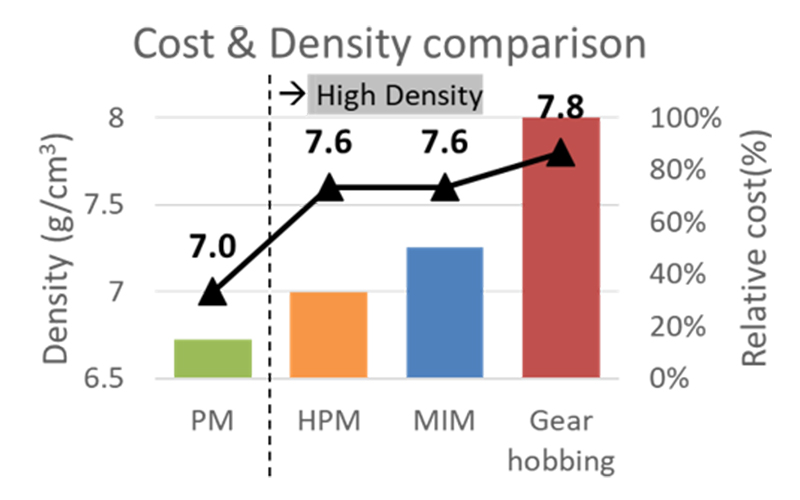

HPM parts have significantly higher density compared to traditional powder metallurgy components.

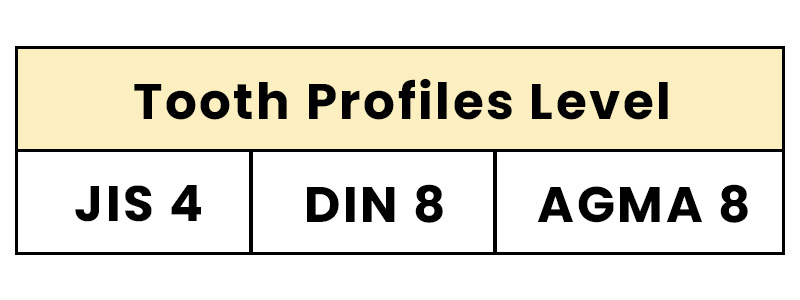

The gear precision of produced parts can meet the highest standards.

Overall strength, including tensile strength, tooth breakage strength, and hardness, is noticeably improved over general powder metallurgy parts.

Compared to parts made by forging, casting, and subsequent machining processes like gear hobbing, the HPM process is highly cost-effective.

Small Gears and Metal Parts smaller than Φ30 x 30 x 15 mm and weighing less than 30g.

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY, thank you.