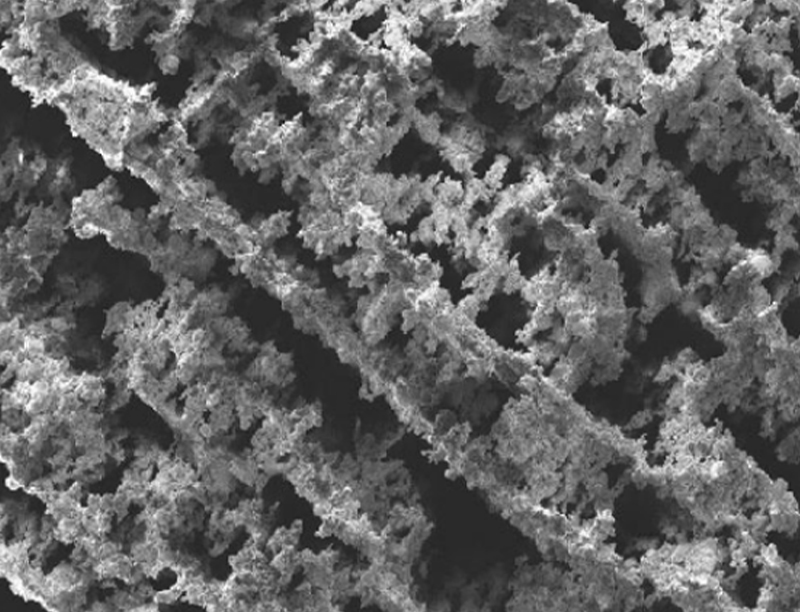

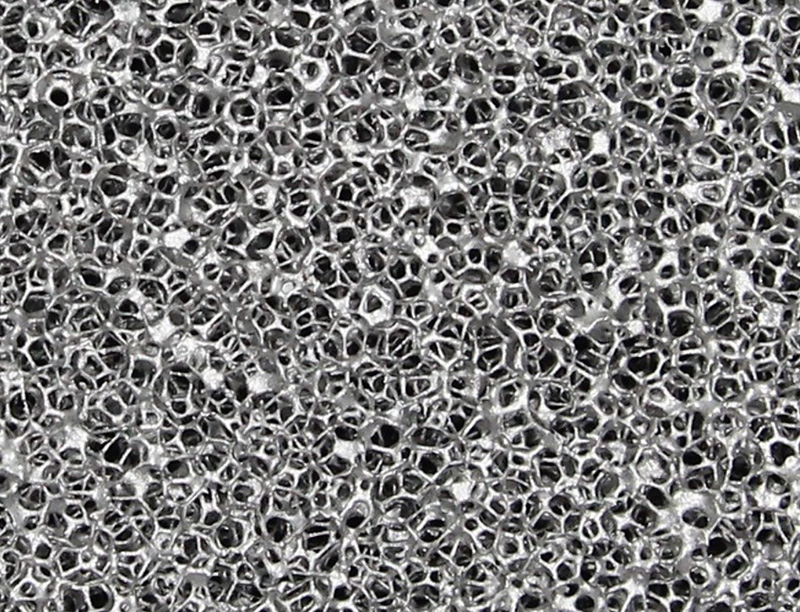

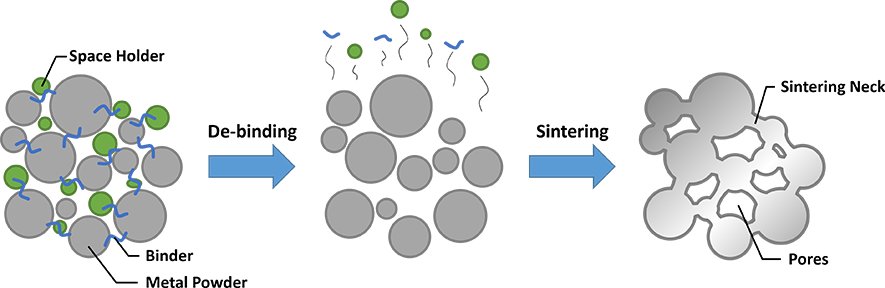

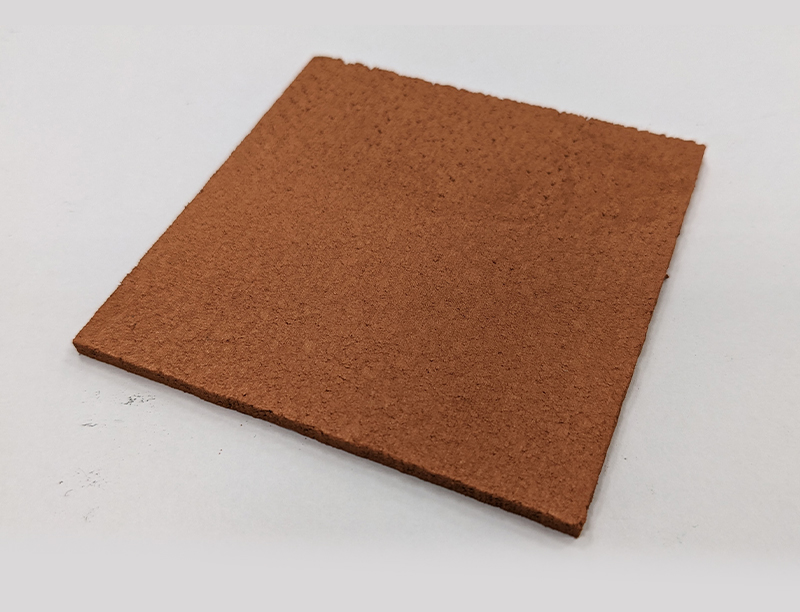

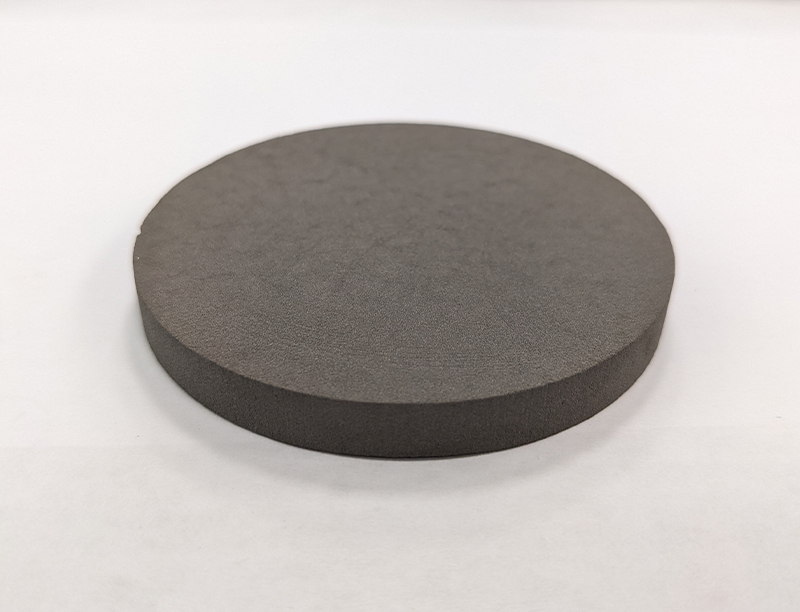

Metal Foam is produced by mixing metal powder with a pore-forming agent, then using a binder to shape and solidify the mixture. The solidified material is subjected to high-temperature sintering to remove the pore-forming agent and binder, creating sintered necks between the metal powder particles, resulting in a porous metal with certain strength.

Freeze Casting (co-developed with Cellmo)

Tape Casting

PU Electrodeposition

| Materials | Copper, iron, nickel, copper-nickel alloy, titanium, aluminum, tungsten, cobalt, and others. |

|---|---|

| Porosity | 30%-90% |

| Pore Size | 1 µm - 1 mm+ |

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY, thank you.