Introduction

Electric motor equipment has a wide range of applications, spanning household appliances, transportation, industrial production, medical devices, and agricultural machinery. These applications all rely on the operation of electric motor modules, making them indispensable in modern human life.

Porite Taiwan primarily produces motor parts that are crucial in motor operation, including bearings and various gears and components used in motor-driven equipment such as actuators and reducers.

Representative Applications Include:

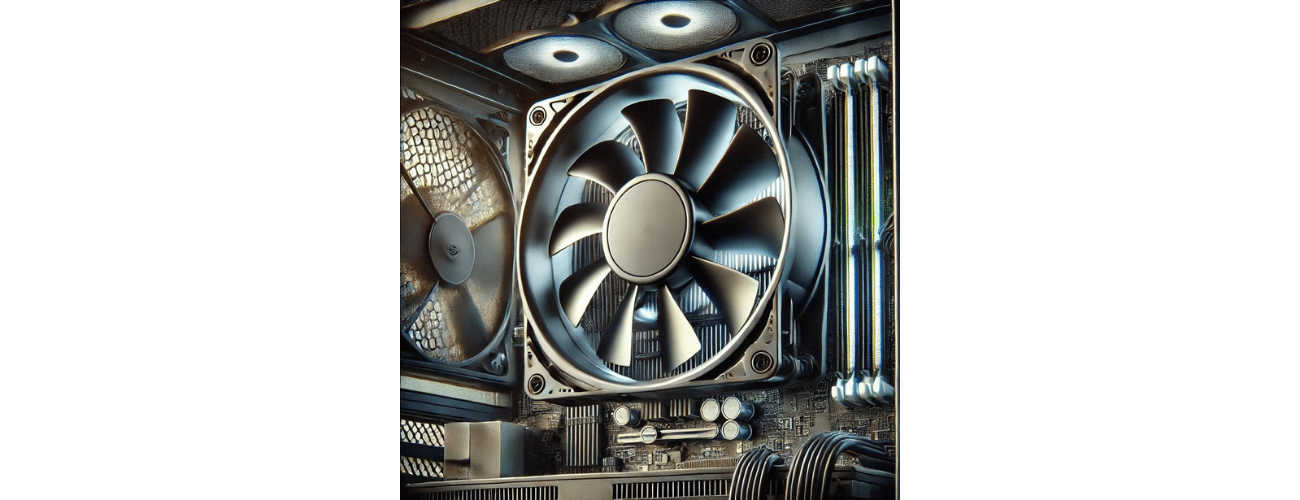

- Fans: Bearings and gears used in the motor operation of various types of fans.

- Automatic Doors: Components such as gears and bearings that ensure smooth and reliable operation of automatic door systems.

- Electric Rolling Doors: Essential parts like gears and bearings that enable the efficient functioning of electric rolling door mechanisms.

Porite Taiwan's high-quality parts are integral to the performance, durability, and efficiency of electric motor systems across these diverse applications.

Applied Area

Fan Components Produced by Porite Taiwan:

1. Bearings: Bearings produced using powder metallurgy technology offer high strength and excellent wear resistance, making them suitable for components in fans that require long operating hours.

2. Motor Parts: This includes parts of the stator and rotor. Powder metallurgy technology enables the production of complex shapes and precise dimensions.

3. Transmission Gears: Some specially designed fans may use gear transmission systems. Powder metallurgy parts are ideal for these high-strength, wear-resistant applications.

On average, a fan product may use 2-4 powder metallurgy parts, depending on the design and complexity of the fan. These parts are mainly used in bearings, core motor components, and some transmission components.

Application of Porite Taiwan's Parts in Automatic Doors:

1. Gears: Gears used in the transmission mechanisms of automatic doors are produced using powder metallurgy technology, allowing for high precision and high strength.

2. Bearings: High-quality bearings are needed in the moving parts of automatic doors to reduce friction and noise. Bearings produced with powder metallurgy technology possess these characteristics.

3. Motor Parts: Some key components within the motor can be manufactured using powder metallurgy technology to achieve high performance and wear resistance.

Transmission Components:

Other transmission components requiring high precision and high strength, such as connectors and brackets, can also be produced using powder metallurgy.

On average, an automatic door product may use 3-5 powder metallurgy parts, depending on the design and complexity of the door.

Application of Porite Taiwan's Powder Metallurgy Parts in Electric Rolling Doors:

1. Gears: Used in the motor and reduction mechanisms, powder metallurgy gears offer high precision, high strength, and excellent wear resistance, making them widely applicable.

2. Bearings: Bearings used in the motor, spool, and transmission mechanisms benefit from the unique porosity of powder metallurgy, providing good durability and reduced friction.

3. Connectors: Connectors such as output shafts that link the motor to the spool and the reducer to other components. The precise dimensions of powder metallurgy parts ensure compatibility with parts made from different materials.

4. Sprockets: In electric rolling doors, the motor drives the sprockets, which in turn move the curtain spool via a chain, allowing the curtain to rise or fall. These gear-like parts are highly suitable for powder metallurgy processes.

5. Brake Structures: These structures control the rise and fall of the rolling door by energizing the coil and utilizing the iron core structure. Powder metallurgy parts can significantly reduce the manufacturing costs of such complex components.

On average, an electric rolling door product may use 3-6 powder metallurgy parts, depending on the design and complexity of the door. These parts are primarily used in key areas such as gears, bearings, and connectors.