Introduction

Porite Taiwan's current production of traditional fuel and hybrid vehicle parts is mainly applied to the engine, interior, transmission, and EPB systems of vehicles.

- Interior Parts: These are primarily used in seat adjusters and window adjusters.

- EPB: Electronic Parking Brake (EPB) system components are critical parts within the braking system. The EPB replaces the traditional mechanical handbrake system with an electronic system controlled by a motor.

- EMB: The Electric Motor Brake (EMB) system, which is entirely motor-controlled, manages braking operations while the vehicle is in motion.

- Transmission Parts: These parts are mainly used in AMT (Automated Manual Transmission) and clutch systems, including synchronizer system parts, clutch hubs, transmission components, planetary gear carriers, turbine hubs, clutches, and concave gears.

- Engine Parts: These parts are primarily used in VVT, transmission, and fuel pumps, including sprockets, cams, pulleys, valve seats, and connecting rods.

- For the increasingly popular electric vehicles market, Porite Taiwan's extensive development and mass production experience can support the co-development of products such as battery connection components, reduction gears, sunroof components, thermal modules, and connectors.

Key Products

Due to the vast number of automotive parts produced, only the most representative parts in various vehicle systems are presented here:

- Engine System:

VVT System Sprocket Variable Valve Timing (VVT) adjusts the timing of valve openings and closings to improve engine performance and fuel efficiency. The optimal valve timing varies under different engine speeds and load conditions. VVT dynamically adjusts valve timing based on these changes. Given its function, VVT system parts require extremely high precision and strength, as well as the ability to withstand long-term operation, necessitating high durability and reliability.

Porite Taiwan’s VVT parts, such as sprockets, are representative products. They are produced using high-tonnage forming machines (500T-800T), high-temperature sintering, and subsequent treatment processes to meet the high-strength demands. - Transmission System:

Synchronizer Gear Synchronizers are mainly used in transmissions to ensure smooth gear shifting. During gear changes, synchronizers align the selected gear and the drive shaft speeds, enabling smooth and noiseless shifts. To ensure smooth transmission operation, synchronizers require high precision gear sets and durability to withstand the continuous impact and wear from shifting.

Porite Taiwan produces synchronizer gears that meet high precision and durability requirements through complex mold design and strict process control. - Steering System:

EPS Pulley The Electric Power Steering (EPS) system uses an electric motor to assist the driver in steering. Traditional hydraulic power steering requires engine power to drive a hydraulic pump, whereas EPS uses electricity and adjusts based on the driver’s steering effort and vehicle speed. Because steering control is crucial for driving safety, parts must be highly precise and durable to ensure stable operation.

Porite Taiwan’s EPS pulleys meet customers’ high precision and strict process capability requirements through rigorous mold design and continuous improvement of production parameters. - Braking System:

EPB Motor Gear The EPB system replaces traditional mechanical hand brakes with an electronic button and motor-controlled parking brake. When the driver presses the button, the Electronic Control Unit (ECU) drives the motor to tighten or release the parking brake. To ensure stable parking, EPB requires high-strength components in its brake and motor parts.

Porite Taiwan produces EPB motor gears, ensuring they meet high strength and durability requirements. These components undergo strict quality management from mold design through production to ensure they perform reliably in vehicles. - Fuel System:

Fuel Pump Inner and Outer Rotors The fuel pump transports fuel from the tank to the engine. Modern vehicles typically use electric fuel pumps, providing stable and high-pressure fuel supply, ensuring engine operation under various conditions. The fuel pump must be durable and strong to withstand continuous pressure and impact.

Porite Taiwan controls design and manufacturing processes to produce high-quality, high-performance fuel pump rotors, meeting stringent automotive industry requirements. - Vehicle Interior:

Car Seat Adjuster Gears Seat adjusters allow drivers and passengers to adjust seat position and angle for optimal comfort and visibility. Modern vehicles often feature electric seat adjusters, allowing adjustment of seat position, height, and tilt via electric motors. Although seat adjusters do not directly affect vehicle movement, they significantly impact driver and passenger comfort, necessitating high strength and durability of components.

Porite Taiwan produces various seat adjuster gears for both mechanical and new electric seat adjusters, ensuring high strength and long-lasting durability to prevent failures over years of use.

Applied Area

The global electric vehicle (EV) market has been flourishing since the launch of the Tesla Model S in 2009. By 2023, EVs accounted for approximately 14% of the total global automotive sales. With the global trends towards carbon reduction and net-zero emissions, the development of the EV market is expected to remain robust for the next 10-20 years.

Currently, Porite Taiwan produces EV parts primarily used in electric vehicle charging ports and steering systems. Additionally, we are continuously expanding our presence in the EV supply chain. Leveraging our technical expertise and decades of experience in the automotive supply chain, Porite Taiwan is committed to providing high-quality components to the EV market.

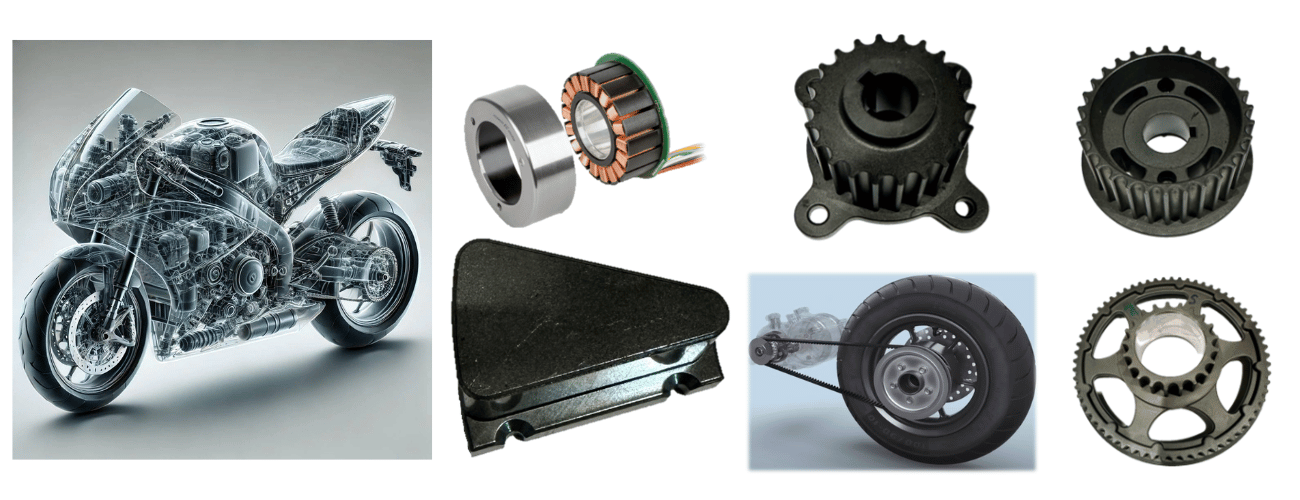

Motorcycles, along with cars, are among the most important modes of transportation for humans in the 20th and 21st centuries. Due to their relatively lower cost, motorcycles are more widely used than cars in developing countries.

Powder metallurgy is highly suitable for producing motorcycle parts. Currently, Porite Taiwan manufactures motorcycle parts primarily used in fuel pumps and transmission systems.

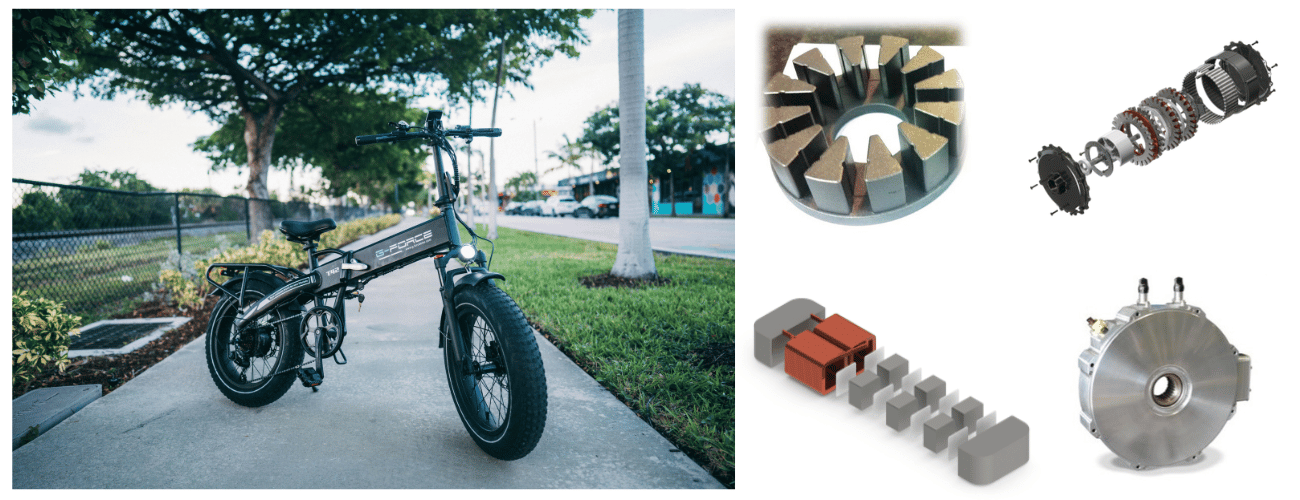

Electric bicycles add an auxiliary power system to the structure of a regular bicycle. Although this increases the overall weight of the bicycle, it provides significant power assistance, making long-distance riding and climbing much easier.

Porite Taiwan is actively expanding into the electric bicycle market, with several development projects either under negotiation or in progress. With market growth and government subsidies, the demand for electric bicycles is expected to continue increasing, driving the demand for Porite Taiwan's components.