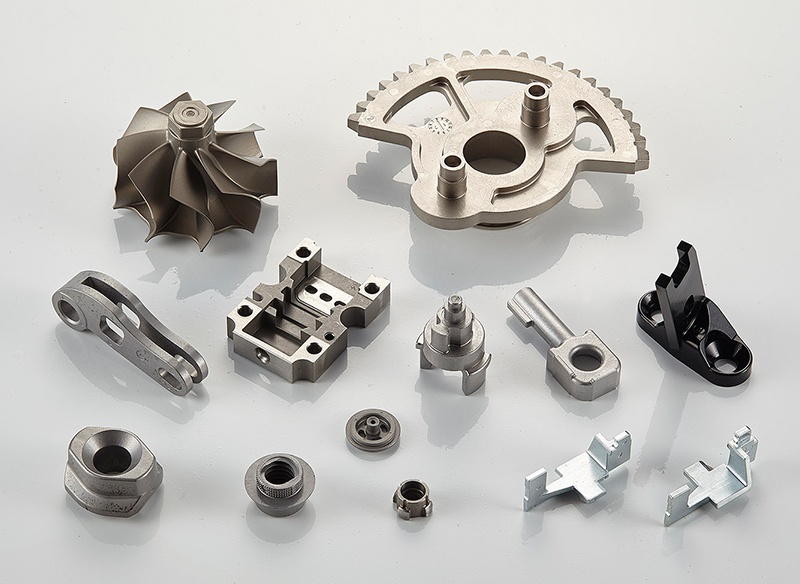

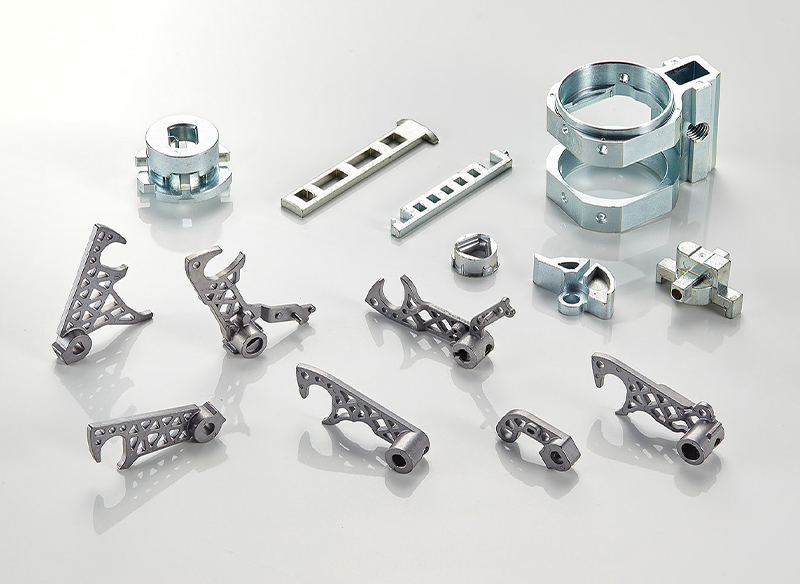

MIM metal powder injection molding is a process specifically used to produce metal parts with special and complex shapes. In terms of dimensional accuracy, MIM far surpasses investment casting, die casting, and cold forging. In terms of mechanical properties and corrosion resistance, MIM also exceeds traditional powder metallurgy.

With over 30 years of experience in MIM technology, Taiwan Porite's MIM products have been recognized and praised by customers in various fields, including automotive (engine and transmission systems), aerospace, nail guns, tools, power tools, 3C industries (computers, communications, consumer electronics), medical, bicycles, and general mechanical parts.

Injection Molding

Mix metal powder with a binder and use a granulator to produce metal materials specifically for injection molding. Then, use an injection molding machine to inject the material into the mold.

Dewaxing

Dissolve the wax on the parts using a solvent.

Sintering

Place the parts into a vacuum sintering furnace for sintering. The temperature causes the parts to shrink, increasing their density and mechanical properties, resulting in the finished product.

The mechanical properties of MIM alloy materials conform to the standards of the American MPIF Standard 35.

| Alloy Steel | Fe-2Ni, Fe-2Ni-0.25Mo (4605), Fe-8Ni |

|---|---|

| Stainless Steel | 316L, 410L, 410, 420J2, 430L, 17-4PH |

| High-Speed Steel | M2 (SKH51) |

| Magnetic Materials | Fe-49Co-2V (Permendure), 78Ni-18Fe-4Mo, Fe-3Si |

| Low Expansion Alloy | Fe-29Ni-17Co (Kovar), Alloy42 (Fe-42Ni) |

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY, thank you.