Porite Taiwan began assembling and producing gearboxes for power tools in 1994. To meet customer needs, the company has invested in advanced production equipment and trained a professional technical team, dedicated to providing high-quality, efficient gearbox products. Years of research and experience have enabled Porite Taiwan to transition from OEM to ODM, developing its own patents related to gearboxes.

Porite Taiwan offers a wide range of gearbox products, from general 3.6V to 24V power tools, producing 1 to 4-speed gearboxes, including impact wrenches and impact drills. The design and production have earned the trust and support of customers. In 2003, the company further expanded the application of power tool gearbox technology to automotive gearboxes. Currently, Porite Taiwan continues to supply global power tool manufacturers and the automotive supply chain.

Preparation Before Assembly

Parts Inspection

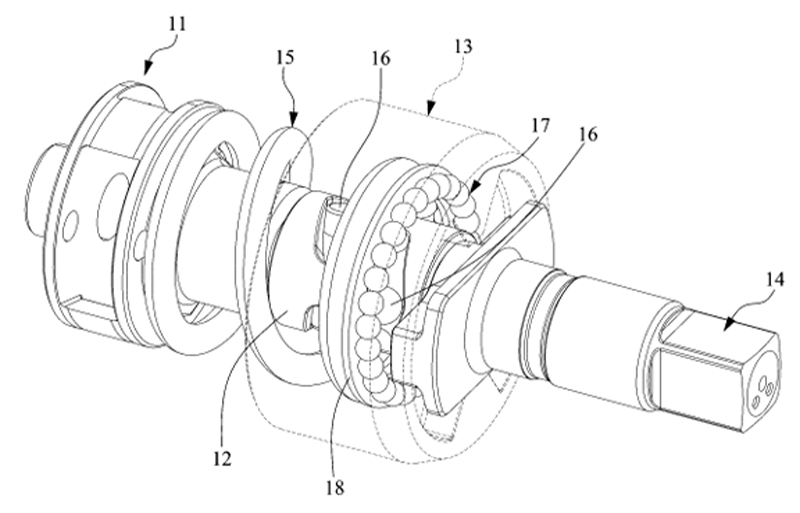

Ensure all parts (gears, bearings, metal components, aluminum parts, plastic parts, etc.) meet design specifications and quality standards.

Assembly

Component Installation

Follow the assembly work instructions to install components, ensuring assembly accuracy and quality standards.

Final Inspection

Function Testing

Perform operational testing of the gearbox to check for smooth operation and ensure there are no abnormal noises or vibrations.

Appearance Inspection

Conduct a visual inspection of the components to ensure product quality before shipment.

Packaging and Delivery

Cleaning

Perform final cleaning of the assembled gearbox to ensure it has a clean appearance.

Packaging

Use appropriate packaging materials to protect the gearbox from damage during transportation.

Labeling and Documentation

Attach relevant labels and inspection documents.

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY, thank you.